Linear Actuators

Linear Actuators

Adapa A/S has fully developed electric actuators for its own use, integrated with a sophisticated control system. Compared to both hydraulic and pneumatic systems, electric actuators are much easier to install, use and it makes maintenance obsolete in virtually all cases.

Adapa´s linear actuators are hi-tech electric devices able to convert rotational motion in low voltage DC stepper motors into linear push/pull movement. Electric actuators are the perfect solution when you need simple, safe, and clean movement with accurate and smooth motion control. Adapa´s linear actuators come in three different categories pulling, or pushing with thrusts from 60kg, 100kg and 200kg, and all that with positional precision of +/-0.2mm.

Adapa´s linear actuators are quiet, clean, non-toxic and energy efficient.

Linear actuators technical data

| Standard Travel range | 200-1000mm |

| Custom Travel range | >1.000 mm with increase in tolerance |

| Max vertical velocity | 5 mm/s |

| Max thrust categories | 60kg, 100kg and 200kg |

| Ingress Protection | IP54 |

-

IP54 Rating and Testing

Adapa A/S Adaptive Moulds – IP rating definition Adapa´s Adaptive Moulds are protected with rating IP 54. 5 – Dust protected Ingress of dust is not totally prevented, but dust shall not penetrate...

-

Linear Actuators 200 – 1000 mm

Linear Actuators standard size 200 – 1.000 mm Adapa’s special designed actuators can be customized to any travel size between 200 and 1.000 mm and stay within the tolerances specified on o...

Technical description

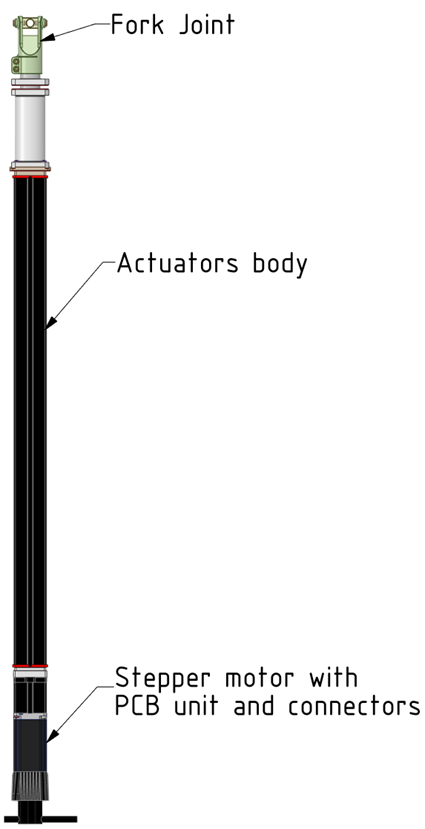

A series of linear actuators are responsible generating the shape of the surface. They are placed in Unicells where the actuators are a middlepoint between the electrical motor system and the membrane support system with magnets, rods, and membrane.

When the user generates a panel using Adapa’s Plug-in, the positions of these actuators is what is being calculated. Each actuator is powered by a stepper motor with high resolution and accuracy. These linear actuators are self-locking, meaning that the machine can be safely turned off while in shape, and it will remain in locked position.

The actuators body together with Fork joint as you can see it on the picture on the left is IP54 rated. As such the actuator body rarely malfunctions.

Actuators body with Fork Joints are no points of maintenance, and thus they do not need to be maintained periodically.

The actuators are to be inspected upon accomplishing 16.000 cycles (one full cycle includes actuators full travel vertically up from the lowest point to the highest point and back). We recommend that our clients to plan and schedule timely maintenance inspection.